Keypad-controlled coolant devices are advanced systems designed to regulate coolant flow with precision. These devices integrate keypad interfaces for easy adjustments, ensuring optimal cooling performance in various applications. Allowing users to set specific parameters enhances efficiency and reliability. These devices are widely used in industries requiring precise thermal management, such as manufacturing and automotive; unlike traditional systems, which rely on manual adjustments, keypad-controlled coolant device provide automation, reducing errors and improving safety. Their ability to maintain consistent temperatures and prevent overheating makes them indispensable in high-performance environments, ensuring longevity and cost savings.

Role in Industrial and Automotive Applications

Keypad-controlled coolant devices play a crucial role in both industrial and automotive settings. They are used in CNC machining, metal cutting, and laser applications to maintain optimal temperatures and extend equipment lifespan. These devices regulate machine and transmission cooling systems in the automotive industry, improving machines' performance and fuel efficiency. Additionally, they are essential in HVAC and refrigeration systems, ensuring consistent cooling and preventing thermal damage. Their precision control helps industries maintain productivity, reduce downtime, and enhance overall safety, making them preferred over traditional cooling methods.

How a Keypad-Controlled Coolant Device Works?

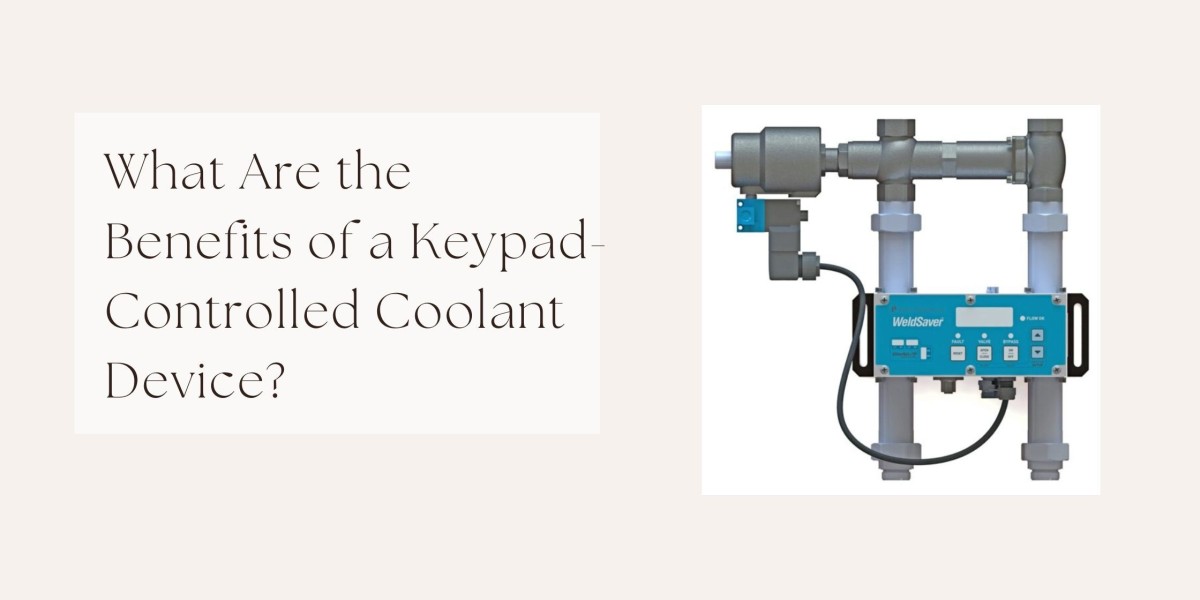

A keypad-controlled coolant device utilizes advanced sensors and microprocessors to monitor and regulate coolant flow. The keypad interface allows users to input desired temperature and flow rate settings, which the system automatically adjusts in real-time. Key components include a coolant reservoir, a pump, flow sensors, temperature sensors, and a control unit. These elements work together to ensure consistent cooling performance by responding to temperature fluctuations and adjusting coolant distribution. This technology eliminates manual intervention, optimizes efficiency, and reduces maintenance requirements while improving precision in cooling applications.

Key Benefits of a Keypad-Controlled Coolant Device

- Precision Control – A keypad-controlled coolant device allows users to regulate coolant flow and temperature accurately. This precision helps maintain optimal operating conditions, reducing errors and ensuring consistent performance in industrial and mechanical applications.

- Increased Efficiency – By optimizing cooling performance, the device minimizes unnecessary coolant usage, reducing waste and improving system efficiency. This leads to better heat dissipation, enhancing machinery longevity and overall productivity while lowering operational costs.

- User-Friendly Operation – Featuring an intuitive keypad interface, the device simplifies adjustments, making it accessible even for non-technical users. This ease of operation ensures quick modifications to cooling parameters without requiring extensive training or complex manual interventions.

- Enhanced Safety – The device prevents overheating and potential system failures by maintaining stable temperature levels. This safety feature protects machinery from damage, reduces the risk of workplace accidents, and ensures uninterrupted operation in industrial settings.

- Cost Savings – Efficient cooling reduces energy consumption and extends equipment lifespan, lowering maintenance expenses. Additionally, precise coolant control minimizes excess usage, further cutting costs associated with replenishment and system repairs.

- Versatility – Designed for compatibility with various industrial and mechanical systems, the device adapts to different cooling requirements. This flexibility makes it a valuable solution for multiple applications, from manufacturing processes to automotive and aerospace industries.

Industries That Benefit from Keypad-Controlled Coolant Devices

These devices are widely used in industries that require precise cooling control. Manufacturing and machining industries utilize them in CNC machines, milling, and grinding applications. The automotive and transportation sectors rely on them for machine and transmission cooling. HVAC and refrigeration systems benefit from their ability to maintain consistent cooling levels. These industries depend on keypad-controlled coolant devices to improve operational efficiency, reduce energy consumption, and enhance system longevity, making them an essential investment for modern industrial and automotive applications.

Conclusion

Keypad-controlled coolant devices represent a significant advancement in cooling technology, offering superior precision, efficiency, and ease of use. Their role in the manufacturing, automotive, and HVAC industries highlights their importance in maintaining optimal performance and preventing system failures. These devices provide substantial long-term benefits by reducing energy consumption, lowering maintenance costs, and improving safety. As industries continue embracing automation, keypad-controlled coolant devices are essential to modern cooling solutions. Proteus Industries Inc. is a leader in providing innovative cooling solutions, ensuring top-tier performance and reliability for various industrial applications.